LED Downlights - A selection guide understandable for everyone

In the past, downlights were available as halogen recessed spots or with larger recessed ceiling lights using incandescent or energy-saving lamps. A homogeneous light emission was ensured by reflectors, which required a correspondingly large installation depth, or diffuse disks. The range of possibilities was limited.

With the introduction of LED, the selection for users has become unmanageable. The following overview should help you to find the right LED downlights for your application.

The ceiling cutout or hole diameter of LED downlights

Especially when changing from conventional recessed ceiling lights to LED downlights, the question of this rarely arises. The hole already exists and accordingly this is more of a limitation with existing buildings. We have set up a filter as a search aid, with which it is possible to limit the number of products displayed in the first step. We offer LED recessed lights for hole diameters from 35mm to 230mm.

But be careful, in many cases the ballast must also fit through the hole. Corresponding information on the dimensions can be found in the data sheets and tables.

If a new building is planned, all possibilities are open with regard to hole diameter and the holes are then drilled according to other luminaire criteria.

The maximum installation depth must also be observed.

Light output & lumen - how bright should it be?

With regard to conventional halogen spotlights, it was easy or you had experience. 20W, 35W or 50W and the number of ceiling spots was decided by the wallet or sometimes existing geometry.

With the use of LED downlights it is often already more sensible to design them using a design software such as Dialux or Relux. But not everyone has these possibilities. Accordingly, we want to offer a very pragmatic approach.

Wikipedia shows examples of illuminance. These show how brightly an area is illuminated. If you want to illuminate a hallway or entrance area with e.g.10 square meters with 100 lux, it theoretically needs a luminous flux of 1000 lumen. (Lux means lumen/sqm). However, light is distributed differently in the room and reflects on the walls, or is swallowed by dark walls, so a surcharge of 1.5 may be given here, which leads to a minimum luminous flux of all LED downlights of 1500 lumens. For example, 4 pieces Fabio 35 á 400 Lux. (for comparison corresponds to approx. 25W Halogen)

Depending on the beam angle, these can be divided into the 10 square meters mentioned in this example.

Beam angle from LED ceiling recessed spots

The beam angle of a luminaire is usually half the highest lux value of the light beam (full half width or `Full Width at Half Maximum', FWHM ). Usually there is a lot of scattered light outside the beam, which causes annoying glare. For this reason, the solution developed by Bartenbach also works with bundle degrees that are based on the level of the 10% lux value (half the full width at half maximum or 'Full Width at Tenth Maximum', FWTM). The Fabio 35 reflector lamp, for example, emits 2 x 18.9 ° at FWHM height and still only 2 x 32.7 ° at FWTM height. In comparison, a standard GU10 halogen lamp only emits at 2 x 12 °, but the beam angle at FWTM level is still far wider than that of the Fabio 35. This means that the standard light bulb creates much more glare than the reflector lamp. In short, the light from Illuxtron LED downlights is used more efficiently thanks to better optics and reflectors, as there is less scattered light and is more pleasant thanks to less glare.

According to the geometric laws (equilateral triangle with beam angle at the top), height also plays a role in the area of illumination. This can be easily calculated with simple mathematics to find the best placement of the LED recessed lights.

Colour temperature / colour rendering index according to location

Most consumers now know the differences in colour temperature and use terms such as "warm white", "neutral white" or "cold white". Unfortunately, this information is only a rough classification. Meanwhile, LED technology and Illuxtron LED downlights are available for color temperatures from 1800K to 5700K. Below is a small overview of the appropriate application.

| Area of application LED downlights | Colour temperature | Colour rendering index/CRI |

| General lighting, apartment, restaurants | 2700K - 3000K | 80 - 90 |

| Office lighting, workplaces | 4000K | > 80 |

| Clothing stores | 3000 - 4000K | > 90 |

| Meat and sausage counters | 1800 - 2200K | > 85, R9 > 80 |

| Bread and baked goods | 2200 - 2700K | > 90 |

Further details regarding special sales requirements can be found in the LUXEON Stylist downlight series developed by Illuxtron.

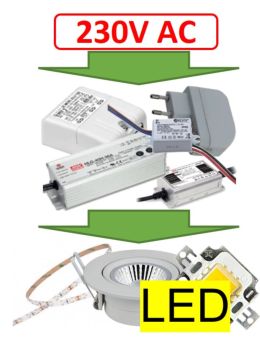

Control and dimming

LED drivers with external control inputs for DALI, 1-10V or a simple push button offer a more convenient and better dimming experience. For more information see LED drivers. For new installations, we favor the option of operating several LED downlights in series with one driver. In existing buildings, it depends on the respective existing installation. Should e.g. GU10 ceiling recessed spots be replaced, 230V mains voltage is already available at the ceiling cutouts.

As an alternative to converting 12V halogen with a central halogen transformer, you can now easily convert to 24V constant voltage operation with a central LED control gear. The respective possible options can be found in the selection menus.